About Calderys

We are a world leader in providing refractory solutions and services. Our value proposition to you is built on combining our world-class refractory product portfolio with our ability to deliver high-quality project management services - from planning and installation, to turnkey delivery and commissioning.

Across all the industries we serve – Iron, Steel, Foundry, Aluminium, Cement, Power, and Petrochem - we deliver to you our promise of superior product performance and value-adding service, thanks to our global network of specialized industry experts and project management professionals.

Partnering you in the foundry industry and more

We are the world’s leading provider of refractory solutions in Foundry, for both ferrous and non-ferrous markets, and have built successful working partnerships worldwide with hundreds of Foundry customers. Our market leadership in Foundry stems from three core points:

Our R&D Focus

We constantly bring new products to you with the aim of delivering productivity gains and cost-efficiency in production of castings.

Our Worldwide Network of Foundry Experts

Our Foundry team is made of experts who are “insiders’’ of the Foundry industry and who understand your business. They bring to you global expertise and high levels of customer service.

Our Unique Model OF Quarry to Furnace

Ownership of mining asset enables us complete process control, ensuring for you high reliability and quality standards.

Our End-to-End Product and Service Offer Dedicated to Foundry Encompasses:

- PRODUCT PORTFOLIO

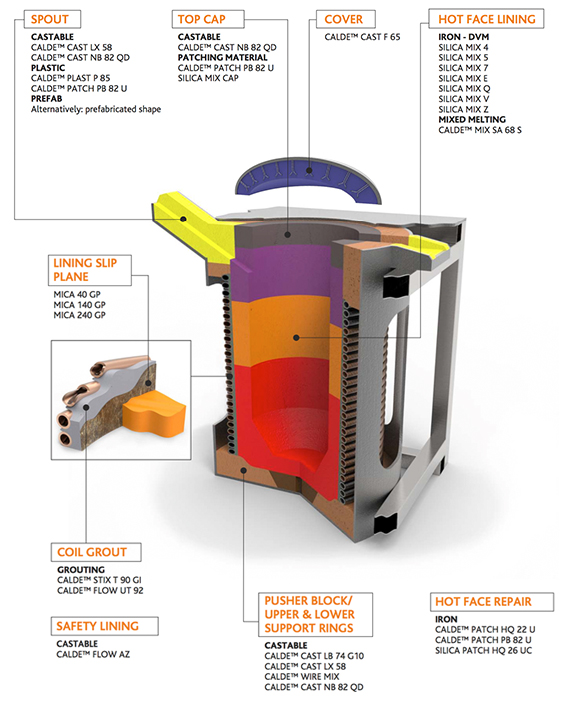

We provide a comprehensive range of refractory solutions for all segments of Foundry industry, including many innovative and ground-breaking products for Coreless induction furnace, Casthouse, Cupola and Channel holding & Pouring. - DESIGN

We provide customized solutions including thermal profiling, product selection, selection of anchoring and insulation materials, development of innovative installation techniques & complete lining design. - LOGISTICS

We ensure timely delivery to your site, and also ensure tracing and monitoring after delivery. - INSTALLATION

We carry out high-quality installation services using in-house equipment and through use of optimal installation techniques. This ensures:

- Low wastage

- Reduction in energy requirements

- Reduction in time required

- Optimal performance of our refractory products - MAINTENANCE

We offer permanent on-site refractory services including regular and predictive maintenance and repairs. We provide rapid round-the-clock response to emergencies and provide instant support on call as required. - PROJECT MANAGEMENT

We provide complete project management services including consultation, planning, delivery scheduling, supervision, site management and also direct training for customer personnel. Our end-to-end project management services ensure on- time and on-budget completion – be it part-service projects or turnkey delivery and commissioning. - MAINTENANCE SERVICE HALL

A new service concept from Calderys wherein we carry out off-site refurbishment of your furnace in our custom-built service halls. This allows timely, safe & hassle-free refractory relining and maintenance of your furnaces.

BENEFITS:

- Reduce downtime allowing minimal disturbance of production due to furnace demolition and relining

- Ensure safe operating conditions as the furnace work is carried out away from production zones or casting areas

- Reduce start-up time of your furnaces as they can be ready pre-dried at our site

- Reduce administrative work, free-up storage area and eliminate unnecessary hassle in your work environment

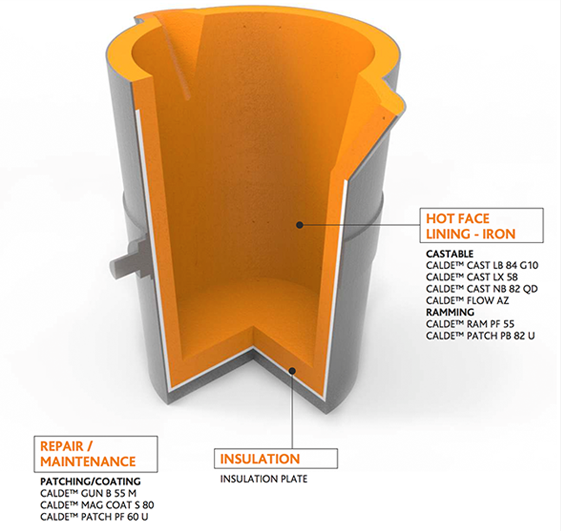

CORELESS INDUCTION FURNACES - IRON

Coreless Induction Furnaces have been a major primary melting unit in the ferrous foundry industry for many years.

The demands placed on the refractory lining are varied and sometimes very complex, bringing very different sets of circumstances that can affect the performance of the refractory lining, including:

THERMAL SHOCK

The constant thermal cycling of the refractory lining

LINING WEAR

Erosion due to the physical movement of the liquid metal.

Corrosion due to the aggressive chemistry of the metal

and/or slag.

GAS PENETRATION

The unwanted movement of gasses through the refractory lining such as carbon monoxide, zinc vapour, and zinc steam can be greatly reduced by our CALDETM SHIELD concept

SLAGBUILD-UP

The deposition of oxides on the refractory lining