Mineral Technologies Inc

MTI PERFORMANCE MATERIAL (11-12)

On May 9, 2014, Minerals Technologies Inc. completed the transaction to acquire all outstanding shares AMCOL International Corporation.

MTI Performance Material is comprised of four key market segments: Metalcasting, Household Personal Care products, Basic Minerals and Advance Performance Additive. Volclay, along with American Colloid Company, comprise the performance material Group of MTI Performance Material and now has become the world's leading suppliers of bentonite products.

Volclay, our metal casting products group produces blended mineral binders containing sodium and calcium bentonites and organic additives sold under the trade name Additrol, Maxicarb and etc. Casting produced from these materials serves automotive, railroad and machine tool markets, among others.

The Volclay brand of bentonite products are recognized worldwide as the standard in many industries, the largest being the metalcasting industry. Volclay bentonite products are used for iron and steel casting production in green sand molding.

PRODUCT TYPES

- Sodium (western) Bentonite

Green sand mold binder that offers high dry compression strength, high dry compression strength, high green deformation, high thermal durability and moderate green compression strength. This product is used by itself in the production of steel and iron castings. It may also be used in combination with calcium (southern) bentonite in iron and non-ferrous applications. Sodium bentonite works best in applications where the metal temperature is high, the sand to metal ratio is low or where there is flaskless molding. - Calcium (southern) Bentonite

Green sand mold binder that offers high green compression strength, high flowability and quick tempering when subjected to mulling energy. This product is used by itself or in combination with sodium bentonite in ferrous and non-ferrous applications. Calcium bentonite is used where lower temperature metals are poured, high sand flow ability is needed, muller energy is low, sand to metal ratios are high and where shakeout energy is low.

PRODUCT NAMES

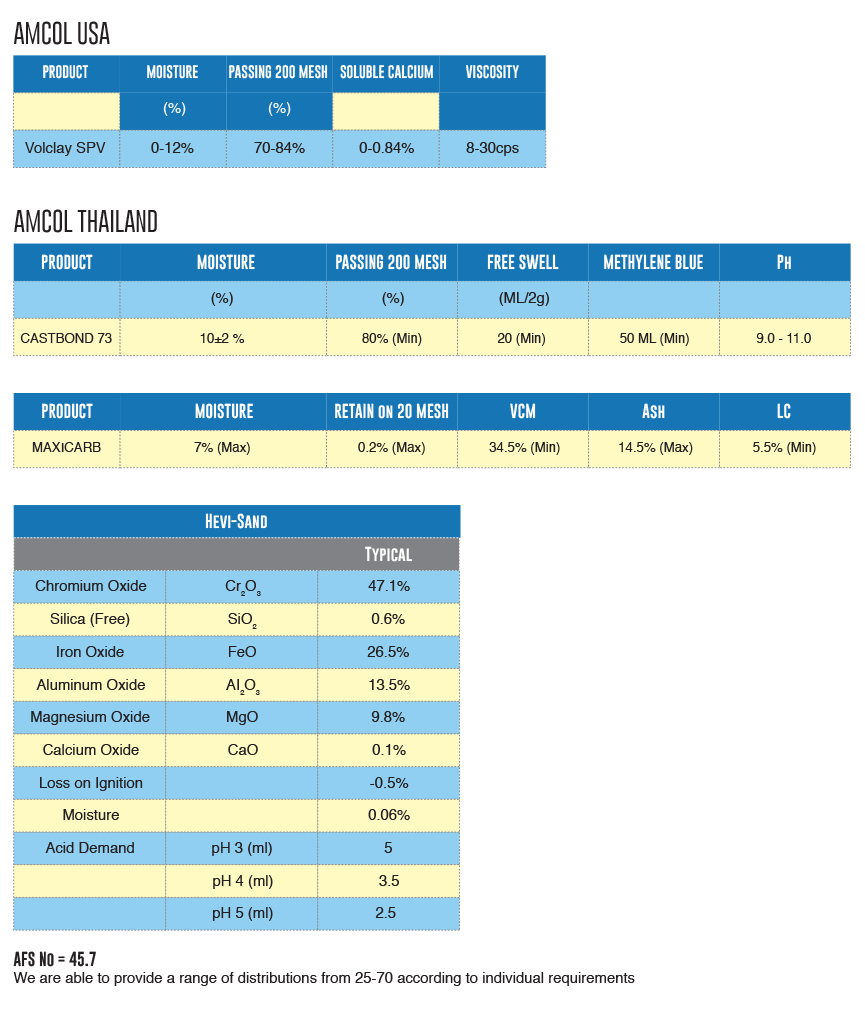

- Volcay-SPV® a high-quality natural sodium bentonite recognized around the world as the metalcasting standard, is used exclusively for iron and steel casting production in green sand molding and for nonferrous production where extra duty is required

- Additrol® and Maxicarb is a custom additive blend of western and/or southern bentonites and carbonecious additives to meet the needs of both ferrous and nonferrous casting producers.

- Hevi-Sand / Chromite Sand: High density & low thermal expansion make this an excellent medium forcore production in high stress, heavy section applications for steel or iron casting production. Because of its high density, cores made from chromite sand are often used to chill a casting section. It may also be used as a green sand medium.

- CAST BOND® A low viscosity bentonite blend exhibits a modified range of mechanical properties Cast Bond is an accurate blend of 2 bentonites designed to meet the specific needs of certain foundries. Cast Bond imparts a more suitable range of Green Compressive, Dry Compressive, and wet Tensile Strengths for certain foundries.

- API-4 (oil & gas) medium to high viscosity activated bentonite exhibiting variable dry particle size. API section 4 material meets and exceeds all of the parameters set out by the American Petroleum Institute classification for a section 4 drilling bentonite. This American Petroleum Institute complied bentonite is applicable for several civil engineering and constructions.

SERVICES

Technical & Sales Support

A key component of American Colloids strength is our advanced laboratory facilities and our team of highly qualified and experienced staff. Our Research and Development laboratory provides extensive product testing and research analysis for new and improved products. Through this support we are better able to partner with our customers and assist them in meeting their competitive challenges.

Lab Capabilities

Our lab has the capability to perform compatibility, moisture, density, permeability, mold hardness (B and C scales), AFS clay, acid demand, pH, metallic content, bulk density, sieve distribution, thermal durability, methylene blue, volatile content matter, stepped volatile content matter, loss on ignition, ammoniacal nitrogen, total hardness, soluble calcium, green shear, wet tensile, green compression, dry compression, and hot compression strength at 1650°F, 1850°F and 2000°F testing.

The Company also offers other specialized testing capabilities that can be performed on request.